What is Brass? Composition, Identification & Brass vs Bronze

• By Richa Kumari

• 2025-12-22

• 26 mins read

Brass is a copper and zinc alloy, known for its warm golden colour, strength, and versatility. When people search what is brass, they’re essentially trying to understand why this metal looks unique and where it fits among other materials like copper or bronze. At its simplest, brass exists because combining copper with zinc creates a metal that is stronger than pure copper, easier to shape, and far more visually appealing. This is why you see brass everywhere, from home décor and utensils to musical instruments, door hardware, and intricate handcrafted pieces.

Brass stands out because of its unmistakable appearance: a rich, golden tone that can range from reddish to bright yellow depending on its composition. It also resists corrosion better than many metals, making it suitable for long term everyday use. In your home, you might already be using brass in door handles, lamps, decorative bowls, puja items, earrings, or even zippers without realising it. Its blend of beauty and durability is exactly why brass has remained relevant for centuries.

This basic understanding sets the stage for exploring its composition, history, identification tests, and how brass compares to bronze in both appearance and performance.

What Are the Components of Brass?

Brass is created from a blend of metals, and each one contributes something specific to the alloy’s colour, strength, and behaviour. The two main components, copper and zinc, decide most of what brass looks and feels like. Smaller additions of other elements improve performance for specialised uses. Breaking these components down helps you understand why brass varies so much across décor, hardware, utensils, and industrial parts.

1. Core Metals in Brass

CopperCopper forms the base of the alloy and gives brass its characteristic warmth and natural golden tone. It also adds durability, antimicrobial properties, and a softer workability that artisans rely on for handcrafted designs. The more copper in the mix, the richer and deeper the colour appears.

ZincZinc brightens the metal, increases strength, and enhances structural rigidity. Higher zinc content makes brass more yellow, harder, and better suited for hardware or industrial components. It’s the balancing metal that adjusts how soft or strong the final alloy becomes.

2. Typical Copper and Zinc Ratios

Most brass alloys contain 55 to 95 percent copper, with zinc making up the remaining portion.

- High copper brass looks warm and reddish-gold

- Balanced copper zinc alloys appear bright yellow

- High zinc brass becomes paler and more rigid

These ratios define everything from colour to workability.

3. Functional Additives in Brass

Brass often includes small, intentional additions of other metals. These fine tune the alloy for specific applications.

- Tin: Enhances corrosion resistance, especially useful in marine or moisture-prone environments.

- Lead: Improves machinability, making it easier to create screws, taps, and precision fittings.

- Aluminium: Adds strength and improves resistance to wear.

- Iron: Increases toughness and helps the alloy withstand mechanical stress.

- Manganese: Boosts hardness and durability.

- Silicon: Helps refine the grain structure and improve wear resistance.

These elements don’t change brass into another material. They simply adjust how the alloy behaves in different conditions.

4. How Each Component Shapes Brass?

Each component shapes a specific aspect of the metal.Copper sets the tone and softness. Zinc brings brightness and strength. Additives like tin or lead fine tune corrosion resistance and machinability. Together, they allow brass to shift between decorative, functional, and industrial uses without losing its visual appeal.

What Is the History of Brass, and How Is It Made?

Brass has one of the longest and most fascinating journeys in the world of metals. It appears in ancient records, archaeological sites, trade routes, and royal artefacts, which tells us that people valued its golden tone long before they fully understood its composition. When we look at the history of brass, we’re essentially looking at how human curiosity, craftsmanship, and early metallurgy slowly evolved into the alloy we use today.

Early Origins of Brass

Brass was first used thousands of years ago, long before people realised it was a copper and zinc alloy. Early brass wasn’t created intentionally. Instead, it formed naturally in regions where copper ores and zinc rich minerals occurred together. When these ores were heated in primitive furnaces, the zinc vapour mixed with molten copper and created a golden alloy that looked different from both metals. Civilisations in India, Rome, Greece, and the Middle East began using it for ornaments, utensils, coins, and decorative items because of its warm colour and easy workability.

How Ancient Brass Was Produced?

Before zinc was isolated as a metal, ancient metalworkers used a method called cementation, where copper was heated with zinc rich minerals like calamine. The process allowed zinc vapours to diffuse into the copper and form brass. The resulting alloy had a distinctive golden tone and was softer than bronze, making it perfect for jewellery, statues, and household artefacts. This low tech but clever process dominated brassmaking for centuries.

How Brass Is Made Today?

Modern brass production is far more controlled. Manufacturers now combine pure copper and refined zinc directly, allowing them to choose precise compositions for specific uses. The metals are melted together in furnaces, refined to remove impurities, and then cast into slabs, sheets, rods, or shapes depending on where the brass will be used. Today’s production includes techniques like continuous casting, hot rolling, extrusion, and forging, which give brass its consistency and strength.

How Brass Composition Evolved Over Time?

As brass spread across countries and industries, its composition kept changing to suit new purposes.

- Early brasses were high in copper because the cementation process limited zinc absorption.

- Later, as metallurgists understood zinc better, balanced copper zinc alloys emerged, giving brighter colours and stronger structures.

- In modern times, tiny additions of tin, lead, aluminium, and manganese have created specialised brass grades for marine, industrial, decorative, and electrical applications.

The evolution of brass reflects the evolution of human technology. What began as a naturally occurring golden metal became one of the world’s most adaptable alloys, used everywhere from temples and homes to ships, instruments, and engineering systems.

Composition of Brass

Brass is made by blending copper and zinc in different proportions, and this simple ratio shift is what creates so many variations of the metal. Most brasses contain 55 to 95 percent copper, with zinc making up the remaining portion. When copper is higher, the metal looks warmer and feels softer. When zinc increases, brass becomes brighter, stronger, and better suited for mechanical or industrial use. This is why the same metal can look reddish in one item and golden-yellow in another.

Copper and Zinc Balance

Every brass alloy begins with copper and zinc, but the way these two metals are balanced changes how the final piece looks and behaves.

High-copper brasses (70–90 percent copper)These alloys have a warm, reddish tone and are typically used in décor pieces, carved home accents, idols, and handcrafted items. They’re soft, easy to work with, and have a classic antique feel.

Mid-range copper brasses (60–70 percent copper)These are the bright, golden-yellow brasses most people recognise. They offer a good balance of strength and appearance, making them ideal for household hardware, trays, bowls, and interior accents.

Lower-copper brasses (55–60 percent copper)Paler in colour and stronger in structure, these grades are meant for industrial components, sturdy fittings, and applications that need durability rather than decorative appeal.

Added Elements and Their Role

Apart from copper and zinc, many brass types include tiny amounts of other metals that fine-tune the alloy for specific purposes.

- Tin improves corrosion resistance, especially in marine environments.

- Lead increases machinability and is often added to make screws, valves, and precise fittings easier to manufacture.

- Aluminium or iron add extra strength and durability for mechanical parts.

- Manganese enhances toughness when brass needs to perform under pressure.

Though these additions are small, they significantly influence how the alloy behaves in real-world use.

How Composition Affects Real-World Grades

- Cartridge Brass (70/30)Higher copper content gives it flexibility, making it ideal for electrical components, artistic sheets, and deep-drawn items.

- Yellow Brass (65/35)The classic bright-yellow alloy used for décor accents, home fittings, trays, platters, and general household items.

- Muntz Metal (60/40)Stronger and more industrial, suitable for marine hardware, architectural panels, and heavy-duty mechanical applications.

- Gilding Metal (90+ percent copper)Rich reddish tone, soft and malleable, commonly used for jewellery, hammered craftwork, and premium décor pieces.

How to Identify Brass Metal?

Identifying brass is easier than most people think. The metal has a few signature traits that help you understand whether an object is pure brass, brass-plated, or a different alloy altogether. These simple, at-home tests can help you verify the metal without damaging it.

1. Check the Colour Tone

Brass naturally has a warm yellow or golden tone, which shifts depending on its copper–zinc ratio. If the metal looks too pale or overly shiny like stainless steel, it may be plated rather than solid.

2. Try the Magnet Test

Brass is not magnetic. If a magnet sticks strongly, the item is either brass-plated or made from an iron-based material. A very faint pull may indicate minor impurities but not pure brass.

3. Listen to the Sound

Tap the object gently with your knuckle. Solid brass creates a deep, warm, ringing sound, while plated or mixed-metal objects sound dull or tinny.

4. Check the Weight

Brass has a noticeable heaviness because of its copper content.If the object feels unusually light for its size, it may be a hollow piece or thin plating over another metal.

5. The Scratch Test (Use Only on Hidden Areas)

Scratch a tiny, hidden spot with a pin or nail. If the colour underneath is still golden, it’s solid brass. If a silvery metal appears below, it’s brass-plated over steel or aluminium.

6. Observe the Patina

Over time, real brass develops a natural brown or greenish patina. Plated items usually flake, chip, or show uneven patches when they age, while pure brass darkens smoothly.

7. Simple Acid Test (Optional & Minimal)

A small drop of lemon juice on a hidden area will brighten real brass immediately. If there’s no change or the surface turns blotchy, the piece is likely plated.

8. When Brass Might Not Be Pure

Some items, especially décor pieces, may be brass-coated to imitate the authentic look.Visible seams, peeling on edges, or iron showing through scratches are reliable signs of plating.

Mechanical Properties of Brass

Brass is valued across industries because it combines strength, flexibility, and resistance in a way that few metals do. Its mechanical behaviour changes depending on the copper–zinc ratio, but the core characteristics remain consistent enough to make it dependable for both everyday objects and precision-engineered components. Understanding these properties helps you recognise why brass is used everywhere from home décor to marine hardware.

A key strength of brass is that it balances durability with workability. It is strong enough to hold shape under pressure, yet soft enough to mould, bend, and machine without cracking. This makes it ideal for detailed craftwork as well as complex industrial parts. Its resistance to corrosion allows brass items to survive moisture-rich environments, while its ability to conduct heat and electricity adds to its versatility.

Below are the properties that define how brass behaves in real-world use:

- Strength and Hardness: Most brass grades have moderate strength, making them suitable for hardware, valves, and home fittings. Alloys with higher zinc are harder and more impact-resistant.

- Ductility and Malleability: Brass bends and stretches without breaking, which is why artisans can carve, emboss, and shape it with ease. This property also benefits industries that require deep drawing or fine machining.

- Corrosion Resistance: Copper in the alloy naturally protects brass from rust, while added elements like tin enhance its performance in coastal and humid areas.

- Thermal Conductivity: Brass heats evenly, making it useful for cookware and objects that benefit from steady heat flow.

- Electrical Conductivity: Although not as conductive as pure copper, brass performs reliably in electrical components, switches, and connectors.

- Acoustic Properties: Its ability to vibrate smoothly makes it suitable for musical instruments, producing a warm and resonant sound.

These mechanical traits make brass adaptable in ways that many metals are not. Whether it is shaped into décor, used as a fitting, or engineered into a specialised component, the alloy maintains consistency in function and form. It’s this balance of beauty, strength, and performance that explains why brass remains relevant across centuries.

Types of Brass Alloys

Brass comes in several alloy families, each created by adjusting how much copper, zinc, and small additive elements go into the mix. These variations change everything, from colour and softness to strength and corrosion resistance so each type serves a different purpose in homes, décor, and industry.

- Alpha brass has low zinc and stays soft and easy to shape, making it ideal for handcrafted décor and engraved pieces.

- Alpha–beta brass balances strength and workability, which is why it’s used for taps, hinges, and everyday hardware.

- Beta brass contains higher zinc, creating a brighter, harder metal suited for heavy-duty industrial parts.

- Free-cutting brass includes a small lead addition for smooth machining, perfect for screws and precision fittings.

- Gilding metal, with high copper content, carries a warm reddish tone and is used for embossing and detailed ornaments.

- Naval brass blends copper, zinc, and tin for excellent seawater resistance, making it reliable in marine settings.

- High-tensile brass is engineered for load-bearing components, while cartridge brass (70/30) offers exceptional ductility for drawn or stretched items.

If you want the deeper technical view, explore in detail: Types of Brass and Their Chemical Composition Explained.

Applications of Brass

Brass is one of the few metals that fits naturally into both traditional craft and modern industry. Its balance of strength, beauty, and corrosion resistance makes it suitable for everything from delicate home decor to heavy mechanical components. Because each brass alloy behaves differently, the metal finds its way into a surprisingly wide range of everyday and specialised uses. In Indian households, kitchenware brass items such as ladles, bowls, and storage jars remain popular because they are sturdy, non-corrosive, and naturally aesthetic.

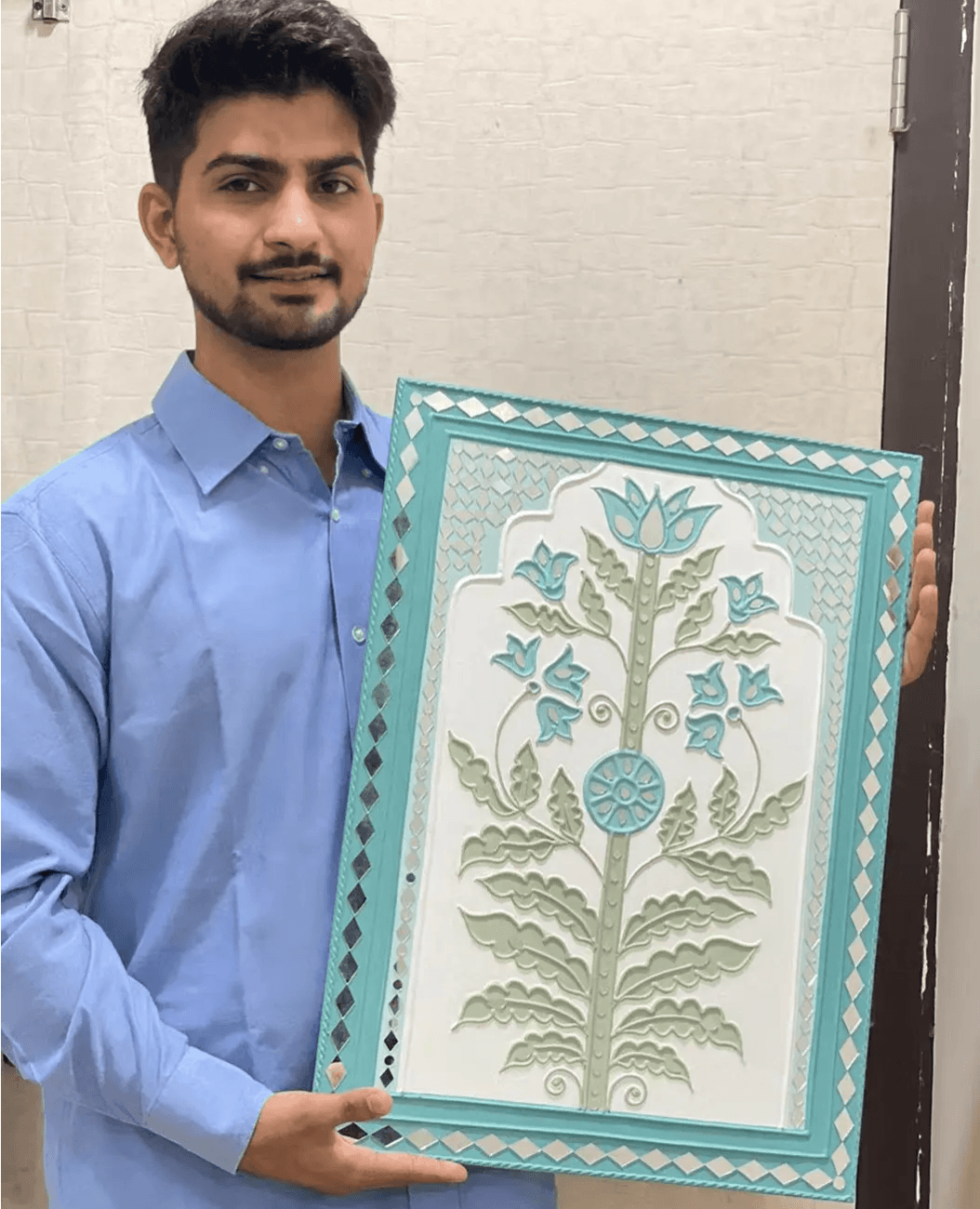

Home Decor and Handicrafts

Brass is widely used for lamps, idols, trays, bowls, candle holders, and statement décor pieces. It moulds beautifully, allowing artisans to engrave patterns, create sculptural shapes, and achieve the warm golden tone that is characteristic of Indian craftsmanship.

Musical Instruments

Instruments like trumpets, saxophones, and horns rely on brass because the alloy vibrates smoothly and produces a rich, resonant sound. The metal’s acoustic quality is one of its most valuable traits.

Electrical Fittings

Many electrical components, including switches, connectors, terminals, and sockets, use brass because it is a reliable conductor of electricity and strong enough to hold precision shapes.

Plumbing and Sanitary Hardware

Brass does not rust in water, which makes it ideal for taps, valves, pipe fittings, and sanitary fixtures. Its durability in moisture-heavy environments keeps it a preferred material even today.

Marine Applications

Naval brass and admiralty brass are used in ships, propellers, pump parts, and marine fasteners. Their enhanced corrosion resistance helps them withstand saltwater exposure better than most metals.

Industrial Components

Brass appears in gears, bearings, sleeves, machinery parts, and precision-engineered components. Its machinability allows industries to create detailed parts consistently.

Automobiles

From radiator cores to connectors and small hardware parts, brass plays a supporting role in automobile engineering because it resists heat and wear.

Home Utensils and Puja Items

Cookware, serving bowls, puja bells, and ritual objects often use brass because it heats evenly, lasts long, and maintains an aesthetic appeal.

Brass continues to be chosen across industries because it performs reliably while offering a distinctive visual and functional character.

Benefits of Using Brass

Brass remains popular because it offers a rare combination of beauty, durability, and practicality. Whether used in a handcrafted décor piece or an everyday utility item, the alloy performs consistently without losing its charm. Its warm golden colour gives it a timeless appeal, while its versatility makes it useful in homes and industries alike.

One of the biggest advantages of brass is that it resists corrosion far better than many metals in its category. This makes it dependable in kitchens, bathrooms, coastal regions, and humid climates. Brass is also naturally antimicrobial, which means its surface discourages the growth of harmful microbes. That is why it has been used for door handles, utensils, and touch surfaces for centuries.

Brass also supports detailed craftwork because of its soft, malleable structure. It bends and shapes easily, allowing artisans to engrave patterns, create idols, and craft décor pieces without compromising strength. At the same time, it maintains stability during machining, which is why industries depend on it for precision components.

A few advantages stand out clearly:

- Corrosion resistance that keeps brass functional in moisture-rich environments.

- Aesthetic appeal with a warm golden tone that suits décor and heritage-inspired designs.

- Antimicrobial properties that make it safer for high-touch surfaces.

- Ease of machining and shaping, useful for both artisanal and industrial work.

- Long lifespan with minimal deterioration.

- Good sound resonance, making it ideal for musical instruments.

- Heat and electrical conductivity, essential for cookware and electrical components.

Because it combines visual elegance with reliable performance, brass remains one of the most adaptable and valued alloys across cultures and industries.

Difference Between Brass and Bronze

Brass and bronze look similar at a glance, but they are two very different alloys. Their composition, colour, strength, and uses vary widely, which is why they show up in different types of products. If you can tell one from the other, you can understand why certain items feel softer, harder, warmer in tone, or more durable.

Composition

- Brass is made from copper and zinc.

- Bronze is made from copper and tin, sometimes with small amounts of aluminium or silicon.

This difference in metal pairing is what sets the entire behaviour of each alloy.

Colour

- Brass usually appears golden yellow and can look bright or warm depending on zinc levels.

- Bronze has a deeper reddish brown tone and becomes even darker as it ages.

Strength and Hardness

- Brass is softer, more workable, and easier to shape or engrave.

- Bronze is harder and more wear resistant, which is why it is used for tools, weapons historically, and industrial components today.

Corrosion Resistance

- Brass performs well in regular moisture but can suffer dezincification in harsh environments.

- Bronze has excellent corrosion resistance, especially in seawater, which is why many marine components are made from it.

Best Uses

- Brass is ideal for décor, hardware, utensils, electrical fittings, musical instruments, and craftwork.

- Bronze suits sculptures, statues, bearings, heavy-duty mechanical parts, and marine applications.

How to Tell Them Apart Quickly?

- Brass is golden and bright.

- Bronze is darker and more reddish.

- Brass feels more malleable when worked on.

- Bronze feels heavier and tougher.

Both metals have their own strengths, but their applications rarely overlap because each alloy is engineered for a different purpose. Brass leans toward beauty, craft, and versatility, while bronze focuses on strength, durability, and reliability in demanding environments.

Manufacturing Technologies That Utilize Brass

Brass adapts easily to different manufacturing methods because it shapes, cuts, and forms without losing stability. This flexibility allows the alloy to be used in both handcrafted and industrial processes.

- Casting creates detailed components by pouring molten brass into moulds.

- Extrusion forms uniform rods, tubes, and profiles by pushing brass through shaped dies.

- Rolling turns brass into sheets and foils for décor, trays, lamps, and machine parts.

- Forging shapes heated brass into strong, durable hardware and load-bearing fittings.

- Deep drawing stretches brass sheets to create seamless items like casings and bowls.

- Machining produces precision screws, connectors, and engineered parts with clean, accurate cuts.

- Die-casting makes intricate, repeatable components with fine surface detail.

This ability to perform across so many techniques is what keeps brass relevant in modern manufacturing.

Limitations and Drawbacks of Brass

While brass is versatile and widely used, it does have certain limitations that affect where and how it should be used. Understanding these drawbacks helps you choose the right alloy for the right purpose.

- Susceptibility to dezincification In very hard water or chemical-heavy environments, zinc can slowly leach out from the alloy. This weakens the metal over time, especially in plumbing components that face constant moisture.

- Tarnishing and surface darkening Brass reacts naturally with air, moisture, and oils from the skin. This leads to oxidation, which causes the surface to turn dull or black unless cleaned and maintained regularly.

- Unsuitable for acidic foods Brass utensils should not be used for lemons, tamarind, vinegar, or other acidic ingredients unless they are properly tin lined. Acids can react with the copper content and affect both taste and safety.

- Lower mechanical strength compared to bronze For applications that require heavy load bearing or high impact resistance, brass falls short. Bronze, steel, or specialised alloys perform better in such demanding conditions.

- Concerns with leaded brass Some industrial brass grades include small quantities of lead to improve machinability. These grades are not recommended for utensils or items that come into contact with food.

- Not ideal for high-pressure environments Brass performs well in regular mechanical settings but can deform under very high pressure or intense mechanical stress. Stronger alloys are preferred in such scenarios.

Brass remains an excellent choice for many applications, but being aware of its limitations ensures it is used safely and effectively

Brass Jar with Lid for Tea or Sugar and Spice in Kitchen Use | Pure Brass

Coffee Dabara Set made with Pure Brass in a Kanjeevaram design theme

Coasters made with Pure Brass in a Matt Hammered Finish | Set of 4 and 6

Brass Tea Strainer & Bowl For Everyday Luxury Kitchen Usage | Handmade In India - 7.5cm x 12.5cm / Brass / Natural

Kitchen Masala or Spice Box in 100% Pure Brass with detachable containers| Organise Your Kitchen Spices in Style

Brass Jar with Lid for Tea or Sugar and Spice in Kitchen Use | Pure Brass | Handmade in India - Brass / Large / Natural

You May also Like

Benefits of Choosing Eco-Friendly Home Decor

• By Anamika

• 2026-01-07

Why choose Handmade Products over Mass-Produced Products

• By Anamika

• 2026-01-07

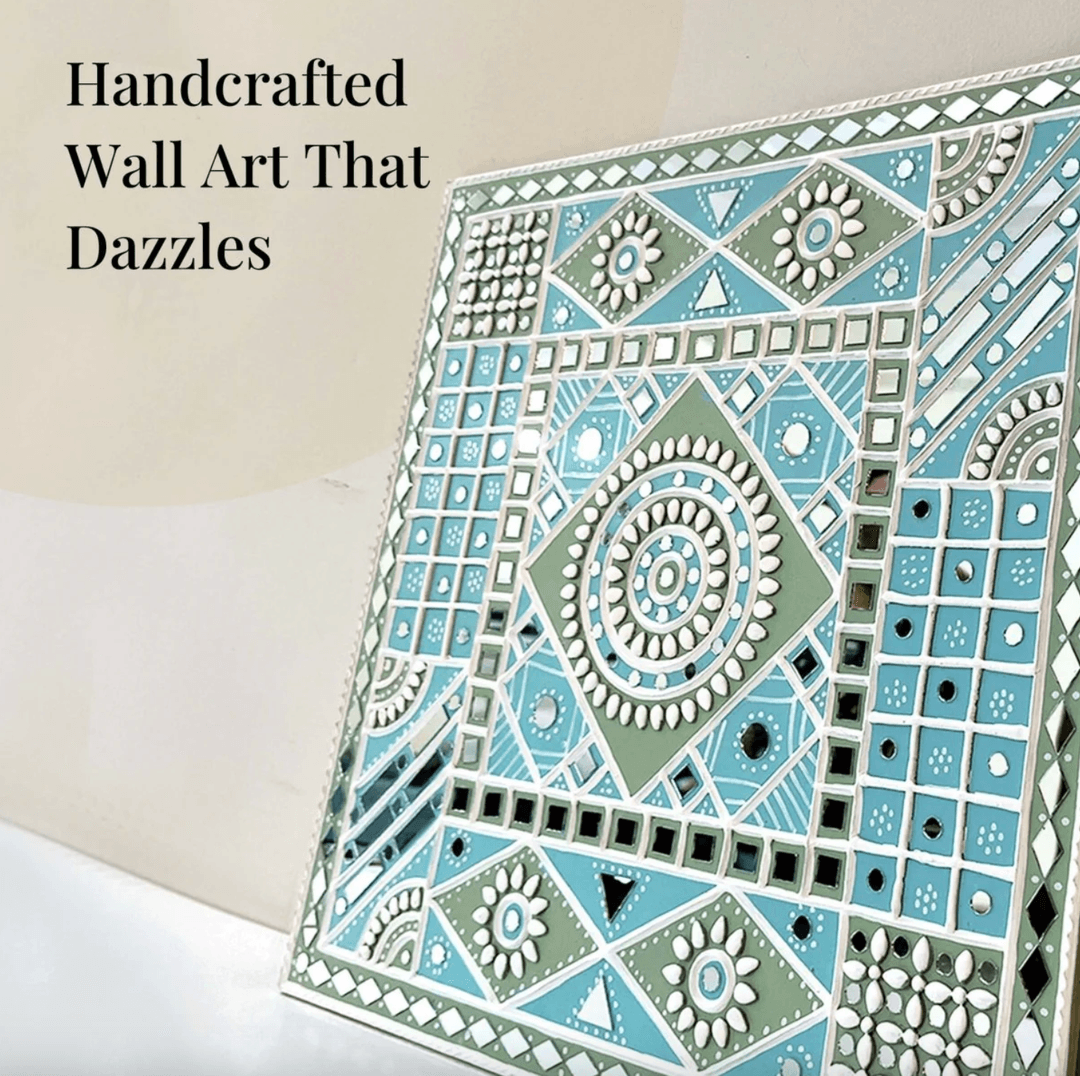

Lippan Art vs Other Indian Wall Arts: Key Differences & Which Is Best for Your Home

• By Richa Kumari

• 2026-01-02

How to Choose the Right Lippan Art Size for Your Wall | Expert Sizing Guide

• By Richa Kumari

• 2026-01-02

How to Select the Right Bedsheet for Summer, Winter & Monsoon

• By Richa Kumari

• 2026-01-02

Frequently Asked Questions

Is brass a pure substance?

No, brass is not pure. It is an alloy made mainly from copper and zinc.

Is brass good for health?

Yes, solid brass is generally safe, especially for décor and utility items. Tin-lined brass utensils are safe for cooking non-acidic foods.

Does brass turn black?

Yes. Brass darkens due to oxidation, moisture, and environmental exposure. Regular cleaning reduces tarnish.

Is brass a good conductor of electricity?

Yes, brass conducts electricity well, which is why it is used in switches, terminals, and connectors.

How many bricks in 1 brass?

In construction, 1 brass equals 100 cubic feet. The number of bricks depends on brick size, but standard estimates fall around 450 to 500 bricks.