Types of Brass and Their Chemical Composition Explained

• By Richa Kumari

• 2025-12-22

• 18 mins read

The types of brass are mainly classified based on their copper and zinc ratio, forming three primary categories: alpha brass, alpha-beta brass, and beta brass. These categories shift depending on how much zinc is mixed with copper, which changes the colour, strength, and behaviour of the alloy. Beyond these core groups, there are also several commercial types of brass such as cartridge brass, yellow brass, naval brass, free-cutting brass, admiralty brass, gilding metal, and Muntz metal, each designed for a specific level of durability, appearance, and performance.

Brass Chemical Composition (Copper, Zinc and Added elements)

Brass is fundamentally an alloy of copper and zinc, and every type of brass begins with this combination. The percentage of zinc is what changes the behaviour of the metal. When zinc is low, brass becomes softer, warmer in colour, and easy to shape. When zinc is higher, brass becomes stronger, brighter, and more suitable for mechanical parts. This simple shift in ratio creates dozens of brass varieties, each with its own character.

Most brasses contain 55 to 95 percent copper, with zinc making up the remaining portion. But to enhance performance, many brass grades also include small amounts of other elements. Tin improves corrosion resistance in marine environments, lead increases machinability, aluminium and iron add strength, and manganese contributes durability. These additions help engineers fine-tune the alloy so it performs better in specific settings.

Understanding the chemical composition is essential because it influences everything from colour and shine to whether the brass is ideal for decor, hardware, or industrial machinery. In simple terms, the formula of metals inside the alloy decides how each brass type looks, feels, and functions.

How Brass Grades Are Classified?

Brass grades are classified based on how much copper and zinc they contain, which creates three major categories known as alpha brass, alpha-beta brass, and beta brass. These categories come from how the metal behaves when the zinc percentage changes. A small shift in zinc content can completely alter the strength, colour, melting point, and workability of the brass. This is why the classification system is essential for understanding which brass type works best for decor, hardware, or industrial use.

When the copper percentage is high and zinc remains low, the metal stays soft, warm toned, and easy to shape. As zinc increases, brass becomes stronger and more suitable for mechanical applications. At very high zinc levels, the alloy becomes harder and more rigid, making it ideal for heavy duty components. These performance changes form the base of the alpha, alpha-beta, and beta classification system used across the world.

The Three Primary Brass Categories

- Alpha brass contains low zinc and is highly ductile, making it perfect for decorative pieces, handcrafted bowls, and intricate designs.

- Alpha-beta brass balances copper and zinc, offering both strength and workable flexibility for items like hinges, valves, and general hardware.

- Beta brass has a high zinc percentage, which increases hardness and makes it ideal for industrial parts that need durability and structural stability.

Together, these categories create a clear framework for identifying brass grades and understanding why certain alloys look richer, feel softer, or perform better in specific applications.

Alpha Brass (Low Zinc Brass) – Composition and Uses

Alpha brass is the type of brass that contains a higher amount of copper and a lower amount of zinc, usually around 65 to 70 percent copper and less than 35 percent zinc. This composition keeps the alloy soft, warm toned, and highly workable. Because the metal stays in a single phase at room temperature, it bends and shapes easily without cracking, which is why artisans prefer this grade for handcrafted pieces. The higher copper content also gives alpha brass its slightly reddish golden colour, a shade often associated with premium decor and traditional craftsmanship.

The metal’s ductility makes it ideal for sheets, carvings, and items that require detailed work. It can be hammered, etched, engraved, or moulded into thin yet strong forms. For home decor, alpha brass creates a richer, more elegant finish compared to brighter yellow brasses with higher zinc content. This makes it a natural choice for bowls, trays, lamps, idols, and artisanal serveware that need both strength and visual warmth.

Key Properties of Alpha Brass

- Soft and ductile due to higher copper content

- easier to shape and carve, ideal for handcrafted designs

- Warm golden colour, preferred for decor and traditional items

- Good corrosion resistance, suitable for indoor use

- Stable structure, making it reliable for detailed workmanship

Because of these qualities, alpha brass remains one of the most widely used brass grades in the world, especially in artistic and decorative applications where elegance and craftsmanship matter.

Alpha-Beta Brass – Composition and Uses

Alpha-beta brass contains a more balanced mix of copper and zinc, typically in the 45 to 55 percent zinc range, which gives it both strength and workable flexibility. This dual phase structure means the alloy is harder than alpha brass but still mouldable enough for shaping and forming. The increase in zinc shifts the colour toward a brighter yellow tone and makes the metal stronger, more resilient, and more suitable for functional applications that require durability.

This type of brass is widely used in hardware because it can withstand daily wear while still being easy enough to machine or cast. Items like door hinges, valves, taps, fasteners, and architectural fittings often rely on alpha-beta brass because it balances performance with a clean polished appearance. It is also a reliable grade for components that need strength without becoming brittle, making it extremely versatile across household and industrial uses.

Key Properties of Alpha-Beta Brass

- Balanced copper and zinc ratio for both strength and workability

- Bright yellow colour, common in hardware and fittings

- Stronger than alpha brass, suitable for frequent use

- Good machinability, making it easier for manufacturers to shape

- Reliable durability, ideal for home fixtures and mechanical parts

Alpha-beta brass is the go to choice when you need a blend of performance and aesthetic appeal, especially for items that must look polished yet withstand regular handling.

Beta Brass – Composition and Uses

Beta brass is the grade with the highest zinc content, often around 45 to 50 percent zinc, which makes it much harder and stronger than both alpha and alpha-beta brass. Because of this high zinc level, the metal shifts into a beta phase structure, giving it increased rigidity, a brighter yellow tone, and a distinctly firm feel. This composition makes beta brass less ductile but far more suitable for applications where strength and resistance to wear are more important than ease of shaping.

The properties of beta brass make it ideal for industrial and mechanical components that need to handle pressure or friction. It is commonly used for gears, locks, screws, heavy duty fasteners, and structural hardware. Manufacturers prefer it for parts that should remain stable under stress, as its hardness makes it hold form even during repeated use. While it is not suitable for detailed carving or handcrafted decor due to its stiffness, beta brass excels in areas where strength is the priority.

Key Properties of Beta Brass

- High zinc content, creating a harder and more rigid alloy

- Strong and wear resistant, suitable for mechanical stress

- Bright yellow appearance, typical of high zinc brasses

- Lower ductility, not ideal for intricate handwork

- Reliable stability, used in industrial and heavy duty parts

Beta brass stands out as the robust end of the brass family, built for performance rather than shaping, and remains essential in engineering and manufacturing.

Common Commercial Brass Grades and Their Chemical Composition

Commercial brass grades are named based on their copper–zinc ratios and the specific elements added to enhance strength, colour, or corrosion resistance. These grades are widely used around the world because each one performs differently. Some are flexible and perfect for forming, some are extremely strong for industrial parts, and others resist seawater, making them ideal for marine environments. Understanding these grades helps you recognise why certain brasses look richer, behave differently, or are chosen for particular applications.

Below is a clear breakdown of the most commonly used commercial brass types and what makes each one unique.

Cartridge Brass (70/30 Brass)

- Composition: Around 70 percent copper and 30 percent zinc

- Appearance: Warm yellow with excellent ductility

- Uses: Cartridges, deep drawn components, lamp fixtures, utensils, and decorative sheets

Yellow Brass (65/35 Brass)

- Composition: About 65 percent copper and 35 percent zinc

- Appearance: Bright yellow, often the classic brass colour people recognise

- Uses: Plumbing fittings, hardware, hinges, and general household components

Red Brass

- Composition: Roughly 85 percent copper, 5 percent tin, and 5 percent zinc

- Appearance: Deep reddish gold because of the high copper content

- Uses: Valves, pipe fittings, ornamental work, and items needing corrosion resistance

Naval Brass

- Composition: About 60 percent copper, 39 percent zinc, and 1 percent tin

- Appearance: Yellow gold with improved durability

- Uses: Marine hardware, propeller shafts, bolts, and components exposed to saltwater

Leaded Free Cutting Brass (C36000)

- Composition: Approximately 60 percent copper, 35 percent zinc, and around 3 percent lead

- Appearance: Bright yellow with exceptional machinability

- Uses: Screws, fasteners, precision parts, and fittings that require detailed machining

Admiralty Brass

- Composition: About 70 percent copper, 29 percent zinc, and 1 percent tin

- Appearance: Warm yellow with improved resistance to corrosion

- Uses: Condenser tubes, heat exchangers, and marine applications needing consistent water resistance

Muntz Metal (60/40 Brass)

- Composition: Roughly 60 percent copper and 40 percent zinc

- Appearance: Strong yellow tone, harder than typical yellow brass

- Uses: Ship sheathing, architectural elements, and heavy duty structural parts

Gilding Metal

- Composition: Around 95 percent copper and 5 percent zinc

- Appearance: Reddish gold, extremely warm toned and soft

- Uses: Jewellery, medals, engravings, and premium decorative accents

These commercial grades reflect how precisely brass can be engineered. A small shift in composition changes colour, strength, corrosion resistance, and the feeling of the metal, which is why brass products never look or behave the same across different uses.

Colour Differences Between Brass Types

The colour of brass changes depending on how much copper or zinc it contains, which is why some brass looks reddish, some looks golden yellow, and some appears pale. This variation is natural and directly linked to the alloy’s chemical composition. Higher copper content creates a deeper, warmer tone, while higher zinc content produces a brighter, sharper yellow shade. When other elements like tin or lead are added, the colour can shift slightly again.

Brasses with 70 percent or more copper tend to look reddish or rose gold, commonly seen in artisanal decor and handcrafted pieces. As zinc content increases, the brass becomes lighter and more yellow, creating the fresh gold tone found in hardware and fittings. In very high zinc alloys, the metal may even appear pale or slightly muted, especially in industrial grades where strength is the focus. These visual differences help identify the type of brass even before knowing its exact composition.

How Composition Affects Colour

- High copper content: Reddish or deep golden tone

- Moderate zinc content: Classic bright yellow colour

- High zinc content: Paler yellow or sharper gold

- Added elements like tin: Slight darkening and enhanced richness

Colour is one of the simplest ways to understand brass types, especially for home decor enthusiasts who want pieces with a warm, premium aesthetic.

Mechanical and Physical Properties of Different Brass Types

Brass properties change noticeably depending on how much copper or zinc the alloy contains, which is why each brass type behaves differently in terms of strength, flexibility, sound, and durability. These properties determine whether a particular brass is suited for decor, hardware, musical instruments, or industrial parts. Understanding these differences helps you recognise why some brass feels soft and warm, while others feel firm, rigid, or engineered for heavy use.

Brasses with high copper content tend to be softer, more ductile, and easier to shape, which makes them ideal for artisanal work and handcrafted decor. As the zinc content increases, the alloy becomes harder and more wear resistant. This shift also affects melting point, corrosion resistance, and machinability. For example, industrial brasses with higher zinc levels perform better in mechanical parts that face constant friction or pressure. Meanwhile, special alloys like naval brass or admiralty brass offer enhanced corrosion resistance in marine or moisture prone environments.

Key Property Differences Across Brass Types

- Strength: Increases as zinc content rises, making high zinc brasses tougher

- Ductility: Higher in copper rich brasses, ideal for forming and carving

- Melting point: Slightly lower in high zinc brasses, affecting manufacturing processes

- Corrosion resistance: Improved by elements like tin, helpful in marine grade brasses

- Machinability: Better in leaded brasses, especially for screws and precision parts

- Acoustic performance: High copper brasses vibrate better, used in musical instruments

These mechanical and physical variations explain why brass is such a versatile metal. A small shift in its composition can completely change how it performs, looks, and feels, allowing it to adapt from elegant decor to industrial machinery.

Which Type of Brass Is Best for Home Decor?

For home decor, the best type of brass is high copper brass, often found in alpha brass or warm tone commercial grades, because it offers a richer colour, better workability, and a more premium handcrafted finish. These brasses contain more copper, which gives them their deep golden tone and makes them easier for artisans to shape into bowls, trays, idols, lamps, and wall decor. This is the grade most commonly used in traditional Indian decor because it ages beautifully and develops a naturally elegant patina over time.

High copper brasses also provide the right balance of softness and stability. They are strong enough to hold their shape yet malleable enough for carving, embossing, engraving, and shaping into thin sheets. This makes them ideal for decor pieces that require craftsmanship, including kitchenware brass items that need to be shaped, engraved, or hammered without cracking. The visual warmth of high copper alloys also makes decor pieces stand out, as their tone blends seamlessly with natural home aesthetics like wood, linen, soft lighting, and earthy palettes.

One example from Peepul Tree that embodies this craftsmanship is the Dhokra Owl, made from high-copper brass, with a handcrafted finish that highlights the warm golden tone and artisanal character ideal for home decor settings.

Why High Copper Brass Works Best for Decor

- Warm toned finish that feels premium

- easy to shape and engrave, perfect for artisanal work

- Develops a graceful patina, adding character with time

- Durable enough for long term display without warping

- Authentic handcrafted appeal that aligns with Indian decor traditions

For premium handcrafted collections like the ones often seen in contemporary Indian homes, high copper brass offers the ideal blend of beauty, durability, and artisanal value.

Small Brass Bowl for Nuts, Snacks & Condiments | Traditional Indian Brass Serveware

Kitchen Masala or Spice Box in 100% Pure Brass with detachable containers| Organise Your Kitchen Spices in Style

Brass Serving Tray Platter - Matt Finish Hammered Serveware | Kitchen Decor Items | Handmade In India - 13 X 4.5 X 1.25 inches / Brass / Natural

Kitchen Storage Jar or Container Set of 3 in Pure Brass. Ideal for Tea, Sugar or Spices| Small, Medium and Large Size

Kitchen Storage Jar or Container made with 100% Pure Brass| Set of 2 with an etched Design

Coffee Dabara Set made with Pure Brass in a Kanjeevaram design theme

You May also Like

Benefits of Choosing Eco-Friendly Home Decor

• By Anamika

• 2026-01-07

Why choose Handmade Products over Mass-Produced Products

• By Anamika

• 2026-01-07

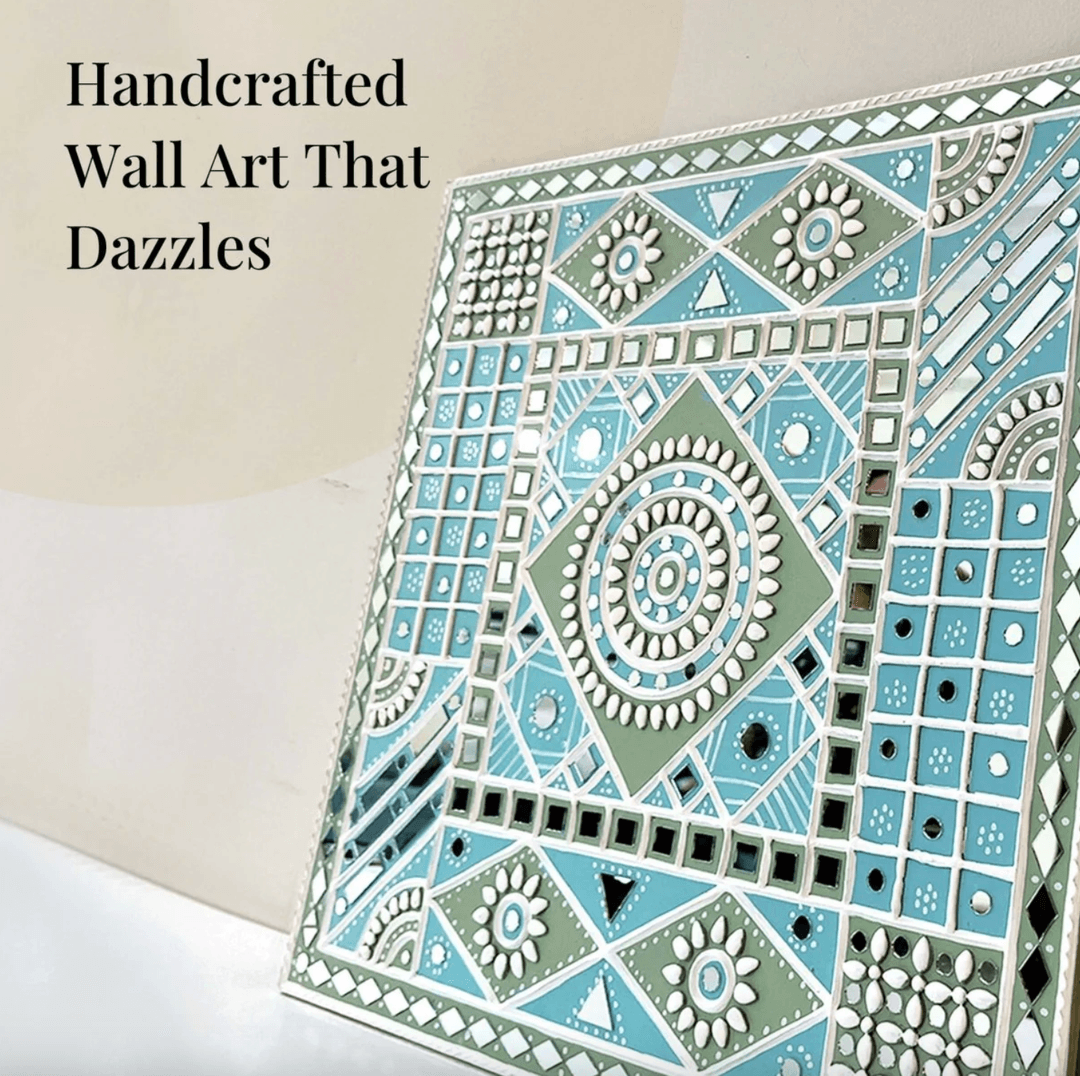

Lippan Art vs Other Indian Wall Arts: Key Differences & Which Is Best for Your Home

• By Richa Kumari

• 2026-01-02

How to Choose the Right Lippan Art Size for Your Wall | Expert Sizing Guide

• By Richa Kumari

• 2026-01-02

How to Select the Right Bedsheet for Summer, Winter & Monsoon

• By Richa Kumari

• 2026-01-02

Frequently Asked Questions

Which brass alloy is the strongest?

High zinc beta brasses and specialised industrial grades like Muntz metal are among the strongest due to their high zinc content and rigid structure.

What is 70/30 brass called?

It is commonly known as cartridge brass, valued for its excellent ductility and warm yellow tone.

Why do some brasses look more yellow than others?

A higher zinc percentage gives brass a brighter, more yellow appearance, while copper rich alloys look deeper and more reddish.

Which brass alloy is used for musical instruments?

High copper brasses and specific acoustic grade alloys are used because they vibrate well and produce a clean, bright sound.

What is lead free brass?

Lead free brass is an environmentally safe alloy that replaces lead with elements like silicon or bismuth while maintaining machinability and performance.